Most optical fibers use silica (SiO2) glass as their core material, but other types of glass are used in specialized applications. The five types of glass used in optical fibers are silica glass, germanosilicate glass, borosilicate glass, chalcogenide glass, and fluoride glass.

This article compares the performance of other fiber optic glass materials using silica as the baseline and closes with a glance at efforts to make high-performance fluoride glass fibers under zero-gravity conditions on the International Space Station (ISS).

Some key parameters of fiber performance include attenuation, wavelength, and dispersion (Figure 1). Performance varies significantly between the different types of glass.

Figure 1. Dispersion refers to the broadening of a pulse as it travels through an optical fiber, which limits the bandwidth. (Image: Fiber Optic Association)

Silica and germanosilicate

Silica is the most common glass used in fiber optics, followed by germanosilicate, a mixture of silica and germanium dioxide (GeO2). Silica offers excellent overall performance in the visible and near-infrared range and is relatively easy to manufacture. However, its absorption increases significantly at longer wavelengths.

Doping silica with a few percent of GeO2 produces germanosilicate, which increases the refractive index and can be used to control dispersion and other properties. For example, while silica’s infrared transmission typically extends to around 2 μm, germanosilicate glass can transmit effectively up to 3 μm, or higher, depending on the formulation.

Borosilicate glass

Doping silica with boron trioxide (B2O3), sometimes supplemented with other compounds such as sodium oxide (Na2O) or aluminum oxide (Al2O3), yields borosilicate glass. Borosilicate fibers are lower in cost compared with silica. They are used when cost, ease of processing, and thermal shock resistance are critical.

Chalcogenide glass

Chalcogenide glass offers much lower attenuation in the mid-IR range compared to silica glass. For instance, they can have about 5 dB/m attenuation at 10 µm wavelength. That compares to attenuation up to 60 dB/m at wavelengths beyond 3 µm for silica.

Chalcogenide glass possesses a much wider transmission window, extending from the visible to the mid-infrared region (0.5 to 25 µm), making it suitable for various infrared applications. The long-wavelength cutoff edge of chalcogenide glass depends on its formulation (Figure 2). The dispersion characteristics of chalcogenide glasses are tunable based on the specific formulation.

Figure 2. Photographs of three chalcogenide glasses (ChGs) using sulfur (S), selenium (Se), and tellurium (Te) (top) and corresponding IR transmission spectra (bottom). (Image: Advances in Optics and Photonics)

Fluoride glass

Fluoride fibers, most notably ZBLAN (Zirconium-Barium-Lanthanum-Aluminum-Sodium), a common type of fluorozirconate glass, offer lower theoretical losses compared with silica and are ideal for mid-infrared applications. Key performance metrics include:

- Lower attenuation in the mid-IR range compared with silica fibers. ZBLAN theoretically can have 10 to 100 times lower losses.

- Transparency over broader spectral ranges, such as 285 nm to 4.5 µm or 310 nm to 5.5 µm. This extends the operating range of ZBLAN to cover the visible to mid-infrared spectrum.

- ZBLAN has lower chromatic dispersion compared to other mid-IR transmitting fibers.

ZBLAN’s performance is strongly dependent on imperfections that arise during production, and high-quality ZBLAN is especially difficult to manufacture.

ZBLAN and microgravity

Using estimates for the theoretical loss limit of ZBLAN, a 2,000-km length of ZBLAN fiber could have the same optical loss as 10 km of silica fiber. Unfortunately, when ZBLAN is produced on Earth, convection and other gravity-driven phenomena cause imperfections. These defects result in the formation of microcrystals that render the fibers unusable for many commercial applications.

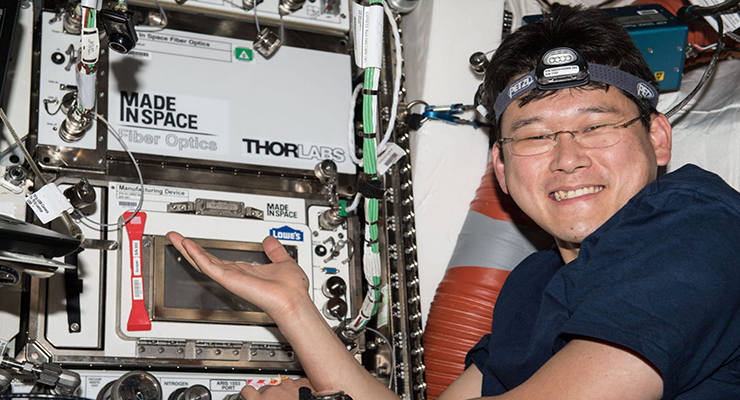

To avoid the adverse effects of gravity, ZBLAN is being produced experimentally in microgravity conditions aboard the ISS. Those experiments could pave the way for future large-scale commercial manufacturing of high-performance ZBLAN in low Earth orbit (Figure 3).

Figure 3. This was made in the Space FOMS Space Facility for Orbital Remote Manufacturing (SpaceFORM) experiment in the ISS, which can make up to 50 km of ZBLAN optical fiber in a single flight. (Image: NASA)

Summary

Silica glass fibers offer the best cost/performance tradeoffs for most applications. Adding GeO2 results in germanosilicate glass, the second-most common material used in optical fibers, and can tune the performance of basic silica. Borosilicate glass offers a lower-cost alternative, while chalcogenide and fluoride glasses are used when high performance is required.

References

Chalcogenide Glass Fibers, Coractive

Exotic Glass Fibers From Space: The Race to Manufacture ZBLAN, ISS National Laboratory

Fluoride glass optical fiber, Thorlabs

Infrared Fibers, Advances in Optics and Photonics

Myths and legends about glass: from the core of an optical fiber, Pyrois Tech

Optical glasses, RP Photonics Encyclopedia

The FOA Reference Guide To Fiber Optics, Fiber Optic Association

Types of Optical Fibers: What You Need to Know, HFCL

EEWorld related content

Where do fiber optics fit into automotive wiring harnesses?

What are the fiber options for 5G fronthaul?

What embedded protocols can you use for optical connectivity?

How can in-package optical interconnects enhance chiplet generative AI performance?

Why use attenuators in quantum computers?