An air compressor for a truck provides a reliable source of compressed air for various tools and tire inflation. It enhances efficiency and productivity during roadside repairs or maintenance tasks.

Air compressors are essential tools for truck owners who seek convenience and reliability. They allow for quick tire inflation and power pneumatic tools, making roadside repairs easier. Many models are portable, designed to fit snugly in truck beds or toolboxes.

These compressors come in various sizes and power ratings, catering to different needs and preferences. Selecting the right air compressor can significantly enhance your trucking experience, ensuring you are always prepared for unexpected situations. Understanding the features and capabilities of different models will help you make an informed choice, ensuring you have the right equipment for any task on the road.

Introduction To Air Compressors For Trucks

Air compressors are vital tools for truck operations. They provide the necessary power for various tasks. From inflating tires to powering air tools, their utility is unmatched. Understanding air compressors can enhance truck performance and efficiency.

Essential Role In Truck Performance

Air compressors play a crucial role in maintaining a truck’s functionality. Here are some key functions:

- Tire Inflation: Keeps tires at the correct pressure.

- Pneumatic Tools: Powers tools like impact wrenches.

- Suspension Systems: Enhances ride quality and stability.

- Braking Systems: Supports air brakes for safe stopping.

Each function contributes to overall truck performance. Proper maintenance ensures long-lasting efficiency.

Types Of Air Compressors For Trucks

Different types of air compressors suit various truck needs. Here’s a breakdown:

| Type | Description | Best For |

|---|---|---|

| Portable Compressors | Lightweight and easy to transport. | Inflating tires on the go. |

| Onboard Compressors | Installed directly in the truck. | Continuous use for air tools. |

| Electric Compressors | Runs on electricity. | Home use or low-demand tasks. |

| Gas-Powered Compressors | Runs on gasoline. | Heavy-duty tasks where power is needed. |

Choosing the right type enhances performance. Consider your specific needs before making a decision.

Benefits Of Upgrading Your Truck’s Air Compressor

Upgrading your truck’s air compressor offers several key benefits. A more efficient air compressor can enhance performance and reliability. Understanding these benefits helps you make informed decisions.

Enhanced Engine Efficiency

Upgrading to a high-quality air compressor boosts engine performance. Here’s how:

- Improved Airflow: Better airflow leads to more power.

- Fuel Efficiency: An efficient compressor reduces fuel consumption.

- Consistent Pressure: Stable air pressure optimizes engine performance.

With enhanced engine efficiency, you save money on fuel. A well-functioning compressor keeps the engine running smoothly.

Improved Air Brake System

A reliable air compressor is crucial for air brakes. Here’s why upgrading matters:

- Faster Response Time: Upgraded compressors provide quicker brake response.

- Enhanced Safety: Better brakes improve overall safety.

- Less Downtime: Fewer repairs mean more time on the road.

With improved air brakes, your truck handles better. This upgrade ensures safer driving conditions for everyone.

Increased Lifespan Of Truck Components

New air compressors can extend the lifespan of various components. Consider these points:

- Reduced Wear and Tear: Efficient compressors lower stress on parts.

- Less Corrosion: Better moisture control prevents rust.

- Lower Maintenance Costs: Fewer repairs save you money long-term.

Investing in a quality air compressor protects your truck. It keeps your vehicle in top shape for years.

Selecting The Right Air Compressor For Your Truck

Choosing the right air compressor for your truck is crucial. It affects performance, efficiency, and your overall driving experience. This guide will help you understand what to consider.

Factors To Consider

Several factors influence your choice of air compressor. Here are the key points:

- Compressor Type: Choose between portable and stationary models.

- Air Pressure: Check the required PSI for your truck.

- Tank Size: Larger tanks provide more air storage.

- Power Source: Decide between electric or gas-powered units.

- Noise Level: Select a quieter option for comfort.

Sizing The Air Compressor

Proper sizing is essential for efficiency. Follow these steps:

- Identify the tools you will use.

- Determine the required CFM (Cubic Feet per Minute).

- Match the compressor’s CFM rating to your needs.

A general rule: choose a compressor with a CFM rating 1.5 times higher than needed. This ensures optimal performance.

| Tool | Required CFM |

|---|---|

| Air Ratchet | 4-5 CFM |

| Impact Wrench | 5-6 CFM |

| Spray Gun | 8-10 CFM |

Popular Brands And Models

Several brands stand out in the market. Here are a few top choices:

- Viair: Known for reliability and efficiency.

- DeWalt: Offers powerful options for heavy-duty use.

- Porter-Cable: Great for portable and lightweight models.

- Makita: Renowned for quiet operation and durability.

Research each brand’s specifications to find the best fit for your truck.

Installation Tips For Maximum Performance

Installing an air compressor for your truck is crucial for optimal performance. Proper installation ensures efficiency and extends the lifespan of the equipment. Follow these tips to achieve the best results.

Step-by-step Guide

- Gather Necessary Tools: Ensure you have all required tools. Common tools include:

- Wrenches

- Screwdrivers

- Hoses

- Mounting brackets

- Choose a Suitable Location: Select a location with proper ventilation. Avoid areas near heat sources.

- Install Mounting Brackets: Securely attach mounting brackets to the truck frame. Ensure they are level.

- Connect Air Lines: Use high-quality hoses for air lines. Ensure all connections are tight to prevent leaks.

- Check Electrical Connections: Ensure proper wiring. Follow manufacturer instructions for electrical setups.

- Test the System: Turn on the compressor and check for air leaks. Make necessary adjustments if needed.

Common Installation Mistakes To Avoid

| Mistake | Consequence |

|---|---|

| Ignoring Manufacturer Guidelines | Leads to performance issues and possible damage. |

| Improper Mounting | Causes vibrations and instability during operation. |

| Using Low-Quality Hoses | Increases risk of air leaks and reduced efficiency. |

| Neglecting Electrical Safety | May result in electrical shorts or fires. |

Pay attention to these common mistakes. They can lead to costly repairs and downtime. Ensure all steps are followed carefully for the best outcome.

Maintenance Best Practices

Keeping your air compressor for trucks in top shape ensures reliable performance. Regular maintenance prevents breakdowns and extends its lifespan. Follow these best practices to maintain your air compressor effectively.

Regular Check-ups

Schedule routine inspections to catch issues early. Here are key areas to check:

- Air Filters: Clean or replace every month.

- Oil Levels: Check weekly and top up as needed.

- Hoses: Inspect for wear or cracks.

- Connections: Ensure all fittings are tight.

Use a maintenance log to track these check-ups. This helps you remember what needs attention.

Troubleshooting Common Issues

Sometimes, your air compressor may face problems. Here are common issues and their fixes:

| Issue | Solution |

|---|---|

| Compressor won’t start | Check power supply and reset the circuit breaker. |

| Low pressure | Inspect air leaks and tighten connections. |

| Overheating | Check for blocked vents and clean the unit. |

Long-term Care For Reliability

Long-term care keeps your air compressor running smoothly. Follow these tips:

- Store Properly: Keep in a dry, cool place.

- Use Quality Oil: Choose oil recommended by the manufacturer.

- Run Regularly: Use the compressor often to prevent rust.

- Seek Professional Help: Hire a technician for annual servicing.

These practices ensure your air compressor remains a reliable tool on the road.

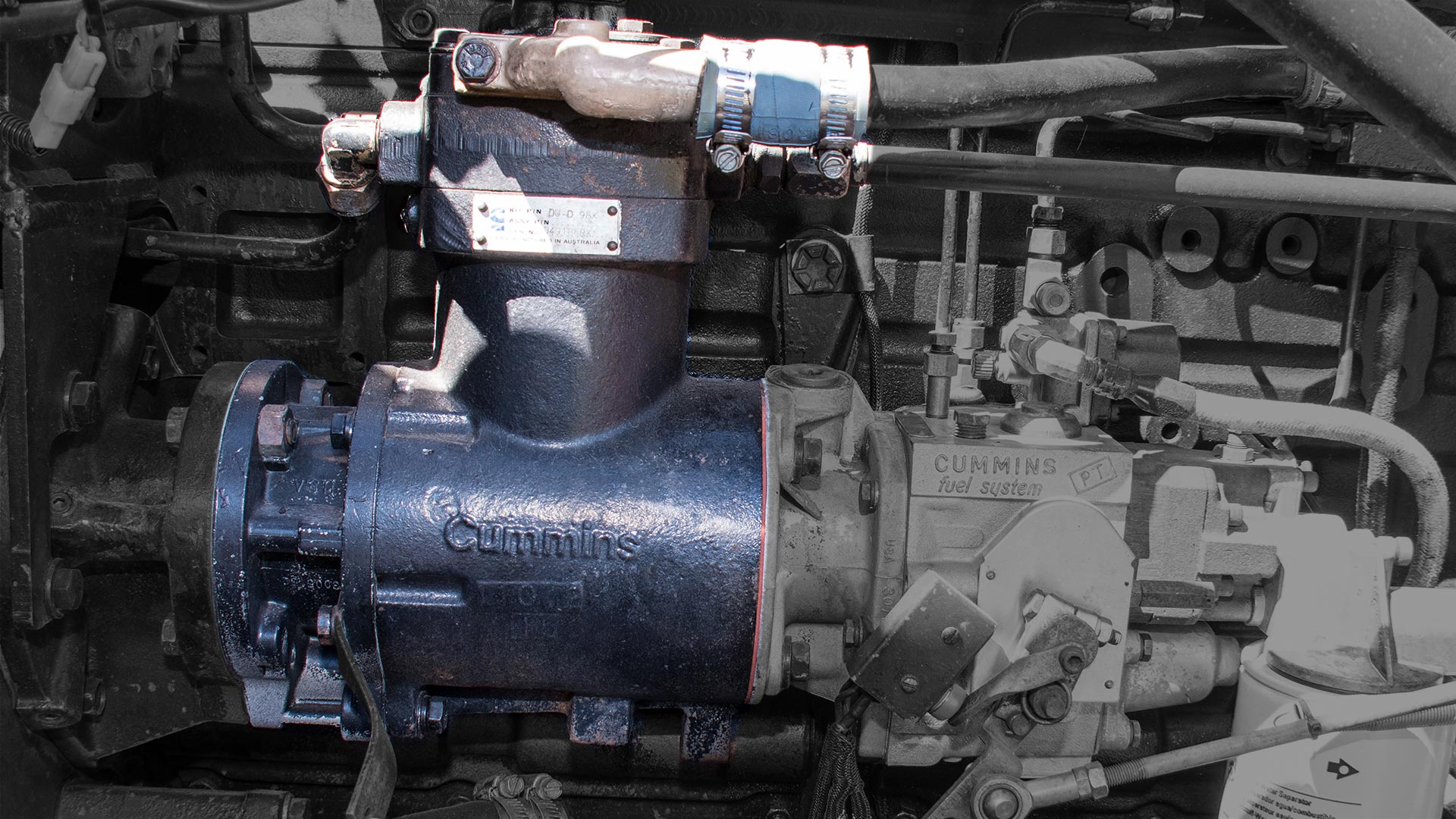

Credit: www.roadtrains.com.au

Performance Tuning And Upgrades

Enhancing the performance of your truck’s air compressor can lead to significant benefits. Tuning and upgrades improve efficiency, power, and reliability. Custom modifications and aftermarket products can take performance to the next level.

Custom Modifications

Custom modifications allow for personalized enhancements. Here are some popular options:

- Custom Air Filters: Improve airflow and filtration.

- Upgraded Hoses: Increase air delivery efficiency.

- Modified Pressure Regulators: Ensure consistent air pressure.

These changes can boost the overall performance of your air compressor.

Aftermarket Products

Aftermarket products provide excellent alternatives to stock components. Consider the following:

| Product | Description |

|---|---|

| High-Performance Compressors | Offer increased airflow and pressure. |

| Upgraded Tanks | Enhance storage capacity for compressed air. |

| Noise Reduction Kits | Minimize operational noise levels. |

These products can significantly enhance your truck’s air compressor performance.

Professional Tuning Options

Consider professional tuning for optimal results. Experts can provide advanced solutions:

- Performance Mapping: Fine-tunes the compressor’s settings.

- Dynamic Balancing: Ensures smooth operation and reduces wear.

- Pressure Calibration: Adjusts for precise air pressure delivery.

Professional tuning ensures your air compressor performs at its best.

Case Studies: Success Stories And Testimonials

Real-world examples show how air compressors transform truck performance. Here are some inspiring stories from both fleet operators and individual truck drivers.

Fleet Improvements With Air Compressor Upgrades

Many fleets have seen major benefits from air compressor upgrades. These upgrades lead to enhanced efficiency and reduced downtime.

- Example 1: A logistics company upgraded its fleet with new air compressors.

- Results: Fuel efficiency improved by 15%.

- Maintenance: Reduced by 20% over six months.

Another fleet reported impressive results:

- Example 2: A regional delivery service installed high-capacity compressors.

- Results: Delivery times decreased by 10%.

- Driver Satisfaction: Increased due to better air pressure control.

| Company | Improvement | Percentage Increase |

|---|---|---|

| Logistics Co. | Fuel Efficiency | 15% |

| Delivery Service | Delivery Speed | 10% |

Individual Truck Performance Enhancements

Individual truck drivers also enjoy significant gains from air compressors. These enhancements lead to better performance on the road.

- Case Study 1: A long-haul driver upgraded to a compact air compressor.

- Result: Tire pressure maintenance became easy and efficient.

- Benefit: Improved tire life by 30%.

Another driver shared their success:

- Case Study 2: A delivery driver installed a portable air compressor.

- Result: Ready to inflate tires anytime.

- Benefit: Reduced delays during deliveries.

| Driver | Upgrade | Performance Boost |

|---|---|---|

| Long-Haul Driver | Compact Air Compressor | 30% Longer Tire Life |

| Delivery Driver | Portable Air Compressor | Fewer Delivery Delays |

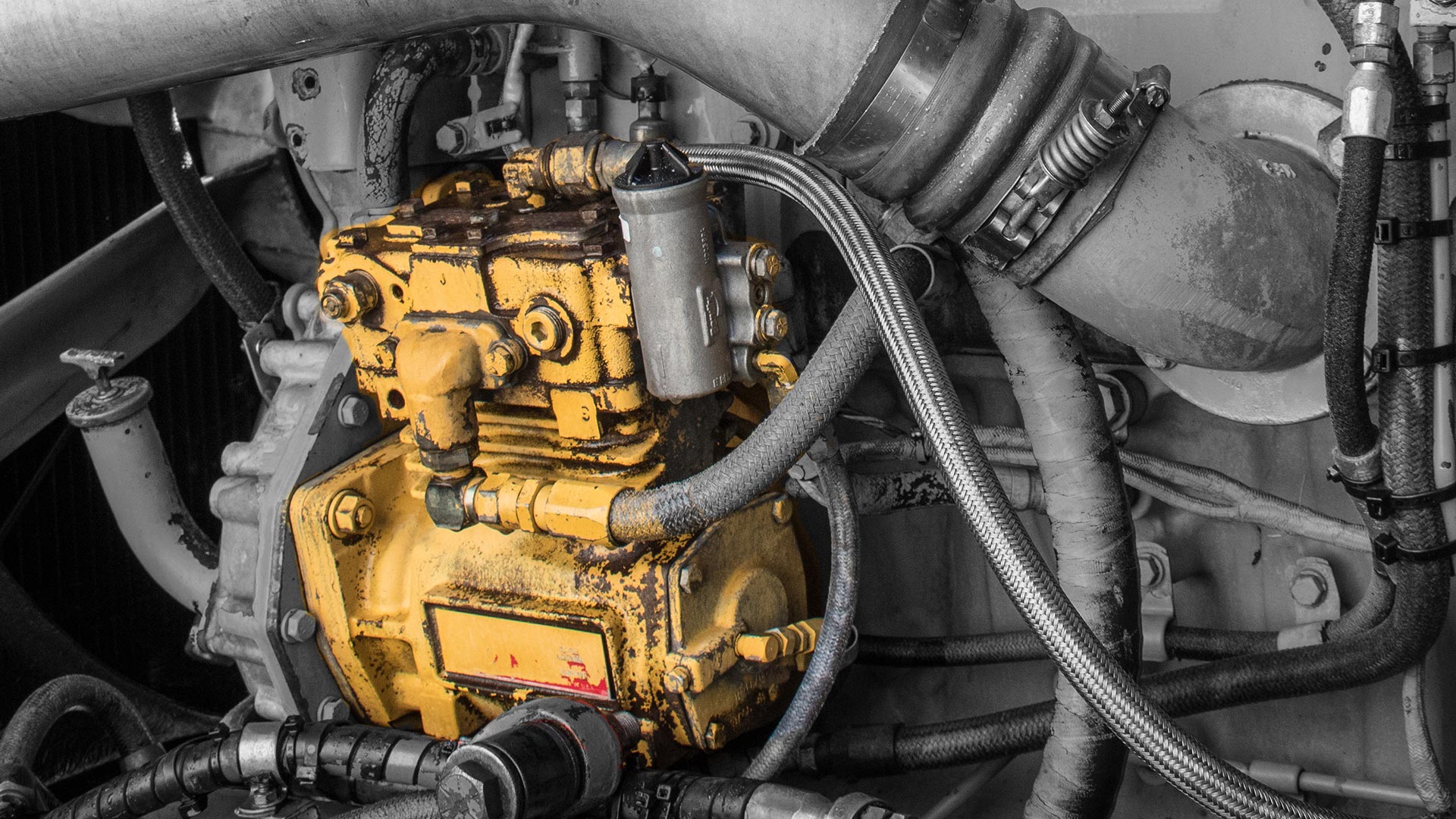

Credit: www.vmacair.com

Future Of Air Compression Technology In Trucks

The future of air compression technology in trucks is bright and innovative. New advancements are changing how trucks use air compressors. These changes will improve efficiency, reduce costs, and minimize environmental impacts.

Innovations On The Horizon

Many new technologies are emerging in air compression for trucks. Here are some key innovations:

- Smart Sensors: These sensors will monitor air pressure in real-time.

- Variable Speed Compressors: These will adjust speed based on need.

- Integration with Telematics: Allows for remote monitoring and control.

- Enhanced Durability: New materials will increase compressor lifespan.

Eco-friendly And Sustainable Options

Environmental concerns are pushing for sustainable air compression solutions. Future options include:

| Technology | Description |

|---|---|

| Electric Compressors | Reduce emissions and noise pollution. |

| Hydrogen-Powered Compressors | Utilize hydrogen fuel for cleaner energy. |

| Recyclable Materials | Use sustainable materials in compressor design. |

Predictions For The Trucking Industry

Experts predict significant changes in the trucking industry due to air compression technology. Key predictions include:

- Increased Efficiency: More efficient compressors will lower fuel costs.

- Regulatory Changes: Stricter emissions standards will drive innovation.

- Shift to Electrification: Many trucks will move toward electric systems.

- Smart Fleet Management: Advanced analytics will optimize operations.

These trends will shape a more efficient and sustainable future for trucking.

Credit: www.roadtrains.com.au

Frequently Asked Questions

What Is An Air Compressor For Trucks?

An air compressor for trucks is a device that compresses air for various applications. It is commonly used to inflate tires, power air tools, and assist in braking systems. A reliable air compressor enhances efficiency and reduces downtime, making it essential for truck maintenance.

How Do I Choose An Air Compressor For My Truck?

When choosing an air compressor, consider factors like pressure and portability. Look for models with higher PSI ratings for better performance. Additionally, assess the compressor’s size and weight to ensure it fits your truck’s storage space and is easy to transport.

Can I Use A Regular Air Compressor For My Truck?

Using a regular air compressor for your truck is possible, but it’s not ideal. Truck air compressors are specifically designed for heavy-duty tasks and higher pressure needs. Regular models may lack the power and durability required for truck applications, leading to inefficiency and potential damage.

How Often Should I Use An Air Compressor For Maintenance?

Regularly using an air compressor for maintenance depends on your truck’s usage. For daily drivers, check tire pressure weekly and inspect air tools monthly. If you often haul heavy loads, more frequent checks are advisable to ensure optimal performance and safety.

Conclusion

Choosing the right air compressor for your truck can enhance efficiency and performance. Prioritize features like portability, power, and tank size to meet your needs. Investing in a quality air compressor ensures you’re prepared for any task. Make the right choice to keep your truck running smoothly and efficiently.