Cleanrooms (sometimes written as two words: “clean rooms”, and historically called “White Rooms” or “Dust-Free Rooms”) are engineered spaces where specialized equipment and procedures are used to maintain a very low concentration of contaminants. While certain levels of cleanliness are desirable for many processes, certain ones can be catastrophically affected by contamination. In the 1960’s, a physicist working for Sandia National Laboratories named Willis Whitfield pioneered the modern cleanroom. His designs focused on continuous filtration of the air inside. This was a real game changer for a number of industries like electronics, pharmaceuticals, semiconductors, and all kinds of scientific research facilities. They can be small – like a dedicated enclosure in a larger building or shop where one or two people perform benchtop testing, assembly, etc. They can also be enormous, like one of the earliest cleanrooms: a 70,000 square foot space at an RCA facility not far from here, in Cambridge, Ohio, where they made control equipment for some of the earliest intercontinental ballistic missiles in the U.S. military’s arsenal.

It should come as no surprise that equipment used in cleanrooms must comply to some demanding standards & specifications. To that end, ISO (The International Organization for Standardization) created ISO Standard 14644-1. It identifies nine Class Numbers, based on allowable particulate concentrations in a given volume of air. Here’s how it breaks those down:

Equipment used inside a cleanroom must be designed, and operated, so as to not increase particulate concentration limits above these limits. You wouldn’t want to use steel tools that are prone to rust, or electric tools with carbon brushes in the motors, for example.

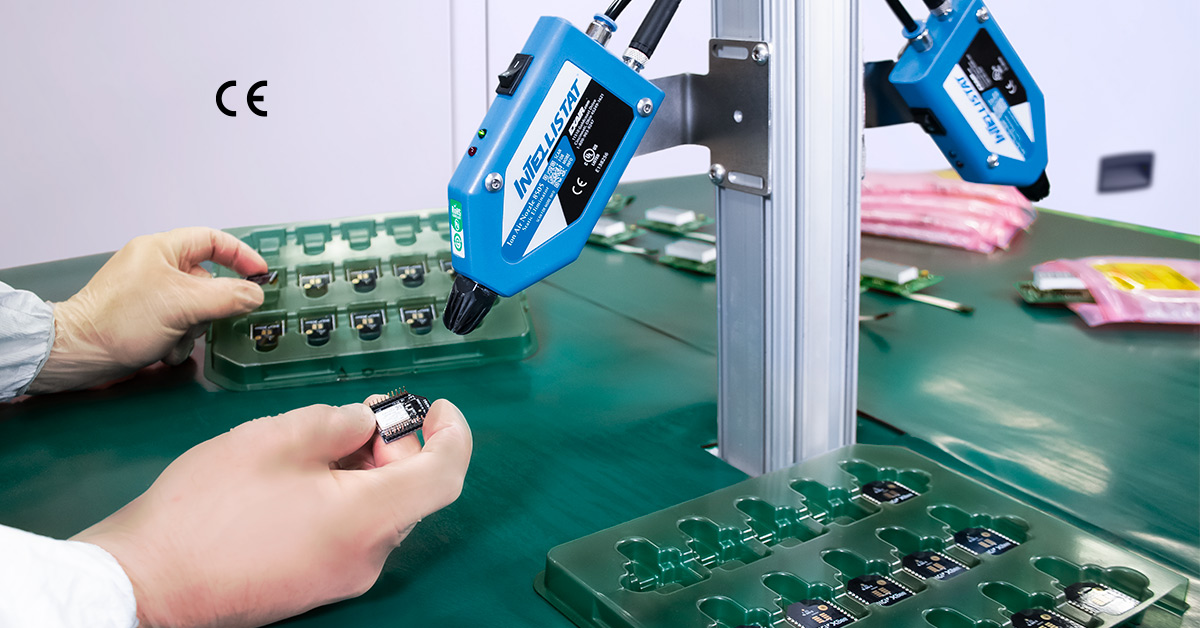

EXAIR’s Intellistat Ion Air Nozzle was designed with these considerations in mind. They were tested by a third part independent laboratory and are classified for use in ISO Class 5 (or below) cleanrooms. This has made them especially popular in pharmaceutical laboratory use, as well as:

- A local eyeglass & camera lens manufacturer uses them to ensure precision measurement instruments’ readings aren’t affected by any residual static charge caused by the grinding process.

- A company that makes overlays for medical devices (IV pump controllers, patient monitoring devices…pretty much anything with pushbuttons you might find in a hospital room or a doctor’s office exam room) uses them to maintain compliance with their customers’ standards.

- A number of food production facilities around the country use them to remove static from processed foods, and packaging containers, during filling operations.

- A manufacturer of packaging machinery includes them on filling machines servicing the food and pharmaceutical industries.

Whether they’re in a cleanroom or not, the compact design, ease of installation & operation, air use efficiency, and quiet operation make them ideal for a range of static elimination applications. If you’d like to find out more the Intellistat Ion Air Nozzle (or its handheld version, the Intellistat Ion Air Gun), give me a call.

Russ Bowman, CCASS

Application Engineer

Visit us on the Web

Follow me on Twitter

Like us on Facebook