Bar clamps slipping can frustrate anyone working on wood projects. It affects the quality of your work.

Understanding why bar clamps slip is crucial. It helps in maintaining precision in woodworking projects. Various factors could cause this issue. Incorrect usage and worn-out parts are common culprits. Sometimes, dust and grime on the clamp can reduce its grip.

Using the wrong size for your project might also lead to slipping. It’s essential to regularly check and clean your tools. Ensure that clamps are in good condition before use. Proper maintenance can prevent slipping. Choose the right clamp size for your work. This ensures a secure hold. By addressing these factors, you improve your woodworking experience. Your projects will be more precise and satisfying.

Buying Guide On Why Do Your Bar Clamps Keep Slipping

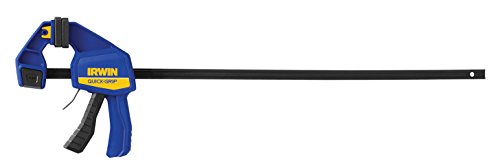

1. Check the bar clamp quality

low-quality bar clamps often slip. Always choose high-quality brands.

2. Inspect the bar for wear

a worn-out bar can cause slipping. Check for smoothness and signs of wear.

3. Ensure proper clamping pressure

apply the right amount of pressure. Too little can cause slipping.

4. Clean the clamping surfaces

dirt and grease on the bar can reduce grip. Clean them regularly.

5. Examine the clamping mechanism

check if the clamping mechanism is functioning well. Replace if necessary.

6. Use the correct size clamp

using the wrong size can lead to slipping. Always match the clamp size to the project.

7. Avoid overloading the clamp

too much load can cause slipping. Know the clamp’s capacity limits.

8. Maintain your clamps

regular maintenance is key. Clean, lubricate, and store properly.

9. Consider using bar clamp pads

pads can improve grip. They help distribute pressure evenly.

10. Replace worn-out parts

worn-out parts can cause slipping. Replace them promptly.

Conclusion

Bar clamps slipping can be frustrating. Understanding why they slip is key to solving the problem. Firstly, ensure your clamps are clean and free of oil. Dirt and oil cause slippage. Check the screw and thread for wear. Replace if necessary.

Also, consider the quality of your clamps. Poor quality clamps often slip under pressure. Always choose reliable brands. Tighten clamps adequately. But not too tight. This prevents damage. Correct usage is crucial. Follow the manufacturer’s instructions carefully. Regular maintenance extends clamp life.

Clean and inspect them frequently. Finally, consider investing in new clamps if problems persist. Old clamps may simply be worn out. Solving the slipping issue improves your work quality. It saves time and frustration. Your projects will be more accurate and professional.

Remember, good tools make a difference. Keep them in top condition. You’ll find your work more enjoyable and efficient.