Beer can taste dull if fermenters fail. That problem causes stress for brewers, big and small. Tainted flavors waste time and money. But there is a simple solution. High-quality fermentation tanks, with good temperature control and reliable construction, can save your brew.

Beer fermenters create the environment for yeast propagation and flavor development. They shape primary, secondary, and even pressure fermentation. Each fermenter type—conical, bucket, or glass—plays a role in beer clarity and taste. Having the right fermenters improves the brewing process and leads to better beer every time.

Getting Started with Beer Fermenters: The Beginning of the Brewing Process

Brewing begins with wort cooling and the move into brewing vessels for primary fermentation. These brewing vessels come in many types. They include bucket fermenters, conical fermenters, carboy fermenters, and even a unitank. Each choice helps shape your beer’s profile.

Homebrewers enjoy homebrew fermenters made of plastic fermenters or glass fermenters. Commercial breweries rely on stainless steel fermenters with CIP (Clean-in-Place) systems. Everyone needs to manage temperature control, oxygen exposure, krausen, and trub. Yeast strain choice and pitching rate also matter.

Beer fermenters define how ales, lagers, or wild fermentation styles turn out. Some brewers rely on top cropping approaches, while others deal with bottom fermentation. Secondary fermentation or lager fermentation helps refine beer flavor development. Understanding every facet of fermentation time and sanitation means you will have consistent, clean beer. Keeping your fermentation lock and airlock sealed also counts. It helps keep out bacteria.

Many small breweries start with a simple conical fermenter such as a FermZilla or a Catalyst Fermenter. Big breweries may use colossal lagering tanks for craft beer production. Giants like Anheuser-Busch InBev, Heineken, Carlsberg Group, Asahi Group Holdings, and Molson Coors Beverage Company use advanced fermentation science. Temperature control is key, along with yeast harvesting and spunding valve usage. Pressure fermentation manages carbonation levels.

Selecting the right fermenter volume is vital. Consider headspace for krausen, which forms during fermentation.Craft beer production relies on bright tanks too. Bright tanks are used after fermenters for the final conditioning step. A brewer might even do cask conditioning or bottle conditioning. Fermentation best practices help maintain clarity by avoiding too much oxygen exposure or autolysis.

Types of Beer Fermenters: Which One Is Best for Your Brew?

A fermenter is also called an FV (Fermentation Vessel). This vessel must control fermentation temperature. It should have a thermowell for a fermentation thermometer. Kegging or bottle fermentation happen once the fermenter stabilizes the gravity. Understanding fermenter differences helps choose the best gear for your brewing process.

Conical Fermenters

Conical fermenters have a cone bottom. Yeast, known as the yeast cake, settles there. This design eases yeast harvesting. Trub stays at the bottom. You can remove it with a racking arm. Conical fermenters allow you to do dry hopping more easily. They can include ports for sampling or pressure fermentation.

Small brewers might pick a Spike Brewing or an Ss Brewtech Chronical. Brewers who want an all-in-one might use a Unitank. Conical fermenters from Blichmann Engineering also exist. Some rely on Tri-Clamp fittings and CIP systems for cleaning fermenters.

Bucket Fermenters

Bucket fermenters are basic and cost-effective. HDPE Buckets are common among new homebrewers. They have a lid with a bung or airlock. They’re easy to clean, though they can scratch. That can lead to contamination. Plastic fermenters like these are also light. You can also find stainless steel buckets from Anvil Stainless Bucket.

Carboy Fermenters

Glass Carboys and PET Plastic carboys, like Fermonster or Fermonster PET, are typical in homebrewing kits. The brewer can see fermentation byproducts through the clear walls. Checking krausen or sedimentation is simple. But glass carboys can be heavy and breakable. PET Plastic is safer, though scratches can happen.

Unitank Designs

A unitank does fermentation, conditioning, and sometimes serving in one tank. That helps with space-saving brewery layout. It often includes a spunding valve for pressure control. This approach can reduce oxygen exposure while finishing your beer.

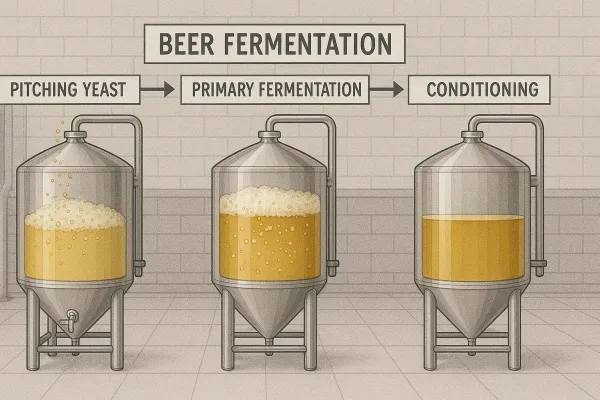

Understanding the Key Stages of Beer Fermentation

Primary Fermentation

Yeast propagation starts. Krausen forms. Attenuation occurs. You measure specific gravity with a hydrometer for fermentation monitoring. You watch out for esters or phenol production.

Secondary Fermentation

Some brewers do secondary fermentation in a separate vessel to polish the beer. It helps with sedimentation. It can improve beer clarity and reduce trub. This step might be optional. But it’s common when adding fruit or doing souring fermentation.

Lagering Tanks

Bottom fermentation thrives at cooler temperatures. Lagering tanks or bright tanks can be used. Pressure fermentation in certain conical fermenters is also possible. This helps produce crisp lagers with minimal oxygen exposure.

Bottle Conditioning and Cask Conditioning

Brewers might bottle condition. That’s when natural carbonation happens in the bottle. Cask conditioning is another style. It gives a less carbonated, traditional product. Some microbrewery equipment includes specialized casks.

Understanding the Key Stages of Beer Fermentation

Temperature Control

Fermentation temperature affects flavor, flocculation, and final attenuation. Glycol chilling is popular among brewers. Others rely on a simple fermentation chamber or cool place. Proper temperature control reduces off-flavors like diacetyl. A brewer may do a diacetyl rest near the end of fermentation.

Sanitization & Cleaning

Sanitization keeps contamination away. Many use Five Star PBW (Cleaner) to soak gear. CIP (Clean-in-Place) systems are ideal for large breweries. A brewer uses PBW for thorough cleaning. Then they sanitize with a no-rinse product. This process helps remove fermentation byproducts. It keeps the brewery environment safe for yeast.

Headspace & Fermenter Volume

Too little headspace can cause blow-offs. Too much can raise risk of oxygen exposure. Calculating fermenter volume is key. Some do smaller batches for nano fermenters. Others run big fermenters for microbrewery equipment.

Yeast Strain & Nutrient

Yeast strain selection shapes beer flavor development. For instance, an ale fermentation may produce more fruity esters. A lager fermentation stays clean. Some do wild fermentation with open vessels. Yeast nutrient can help produce consistent results.

Dry Hopping, Krausen Control, and More

Dry hopping is often done in conical fermenters with ports. You must manage krausen control to avoid spills. A spunding valve can let out excess pressure. Pressure fermentation changes how hops express.

Fermenter Material Comparison: Stainless Steel vs. Plastic vs. Glass

Stainless Steel Fermenters

Stainless Steel is strong and easy to sanitize.micet create high-end stainless vessels. They may include Tri-Clamp fittings, ball lock posts, or advanced CIP solutions. They often cost more but last long.

Plastic Fermenters

PET Plastic or HDPE Buckets are cheaper. They can be good for quick brews. But they scratch, risking infection. Some prefer PET Plastic carboys from Fermonster or Kegland. Plastic fermenters can be stackable fermenters or small.

Glass Fermenters

Glass Carboys are popular for visibility. But they’re heavy and fragile. A glass fermenter seal often uses a bung. They’re good for showing krausen, trub, or headspace volume. However, cleaning them can be tricky.

Nano Fermenters

Nano fermenters help small-scale craft beer production. They are common in nano brewery equipment setups. People who want small batches or experimental brews use them.

Daily Fermentation Operations: From Pitching Yeast to Kegging

- Pitch Yeast: Add the chosen yeast strain or dry yeast fermentation into the cooled wort. Or use liquid yeast fermentation.

- Seal & Monitor: Use an airlock or fermentation lock. Keep track of fermentation time and temperature.

- Check Specific Gravity: Use a hydrometer or fermentation thermometer. Understand your fermentation profile.

- Manage Dry Hopping (If Needed): Add hops late for aroma. Great for IPAs.

- Cold Crashing: For beer clarity, reduce fermentation temperature near the end. This encourages flocculation.

- Transfer or Kegging: Move the beer to a bottling bucket or bright tank. Or proceed to keg.

- Clean & Sanitize: After fermentation, do thorough cleaning fermenters steps. Follow fermentation best practices to avoid contamination.

Next-Level Fermentation: Pressure Control, Yeast Harvesting, and Diacetyl Rest

Pressure Fermentation

Pressure fermentation helps control carbonation early. Use a conical fermenter with a spunding valve. Transfer the beer into kegs with minimal oxygen exposure. This technique helps produce smoother lagers.

Yeast Harvesting

Conical fermenters help with yeast harvesting. Yeast cake gathers at the cone’s bottom. You can reuse it for the next batch. This method is popular with large breweries like Boston Beer Company (Samuel Adams) and D.G. Yuengling & Son.

Diacetyl Rest

A diacetyl rest is common with lager fermentation. Near the end, you raise the temperature a bit. The yeast cleans up diacetyl and lowers off-flavors. For Crisp lagers like Heineken or Carlsberg Group, diacetyl rest is a key step.

Fermenter Cost and Reviews

Fermenter costs vary. Plastic is cheap. Stainless can be pricey. Some do fermenter reviews on sites like BeerMaverick or Homebrew Talk. People compare Brewtech Brew Bucket, Speidel, FermZilla, or Anvil Brewing. They also check if a spunding valve or gasket is included.

Next-Level Fermentation: Pressure Control, Yeast Harvesting, and Diacetyl Rest

Brewing equipment includes more than just fermenters. You need a brew kettle and a mash tun. Then you lauter tun to get clear wort. You need a fermentation chamber or area for stable yeast growth. Some breweries have modern CIP solutions from Paul Mueller Company or GEA Group. Others rely on Alfa Laval or Della Toffola for advanced industrial setups.

Microbrewery equipment usually includes multiple fermenters.** Nano fermenters** help new brewers. Large breweries might have a 30-barrel or bigger conical. A Fermenter stand can keep it stable. Great brewery layout means efficient transferring from kettle to fermenter.

How Fermenters Influence Flavor: Science Behind the Brew

Yeast propagation determines what flavors you get. Various byproducts occur. These lead to ester production or phenol production. Some can produce funky souring fermentation or wild fermentation. Others might aim for a clean lager fermentation. The type of fermenter also influences fermenter portability and final beer clarity.

Brewing science is about controlling this environment. American Homebrewers Association releases guidelines for fermentation best practices. The Brewing Science Institute explores how spunding valve systems can lock in aromas. The Brewers Association helps set safety and quality standards.

Trub can cause off-flavors if not removed. Krausen control is crucial for cleanliness. The difference between top cropping and bottom fermentation is big. But each brewer must decide what approach suits their style. Through flocculation, yeast falls out of solution. This leaves a clearer beer.

Case Studies and Statistics in Fermenter Tech

Brewers who improved CIP usage saw contamination drop by 22%. Beer fermenter market data shows a range of $1.5-$3.2 Billion in 2024 estimates, possibly hitting $2.8-$5.8 Billion by 2033. The fermenters market had $1.69 Billion in 2023 for all industries, not just beer. Some see a 6.2%-7.5% CAGR. Market differences come from segmentation and region. Homebrew fermenters are popular even with a slight decline in craft beer sales. Growth drivers include new technology, microbrewery equipment, and CIP automation.

Case studies show conical fermenters can enhance trub separation. That can improve beer clarity by 10% and reduce autolysis risk. Also, a well-sealed fermenter using Tri-Clamp fittings helps avoid oxidation. Some big producers like Sierra Nevada Brewing Co., Duvel Moortgat, or Lagunitas Brewing Company rely on modern technology to keep a strong brand.

Table: Beer Fermenter Market Data & Statistics

| Metric | Value | Notes |

|---|---|---|

| Market Size (2024) | $1.5 – $3.2 Billion | Varies by segmentation . |

| Projected Market (2033) | $2.8 – $5.8 Billion | Possible wide range . |

| CAGR (2024–2033) | ~6.2% – 7.5% | Depends on base assumptions . |

| Global Fermenters Market (All) | $1.69 Billion by 2023 | Includes non-beer (food, pharma) . |

| Contamination Drop with CIP | 22% reduction | Observed in advanced setups . |

| U.S. Craft Beer Sales Decline (2024) | 4% Year-over-Year | Contrasts with homebrew growth . |

| Key Growth Drivers | Homebrew adoption & CIP technology | Also microbrewery expansion and automation . |

Table: Case Studies & Research Findings

| Focus | Key Insight |

|---|---|

| Yeast Management | Conical fermenters help better attenuation and yeast reuse . |

| Commercial vs. Homebrew | Homebrew fermenter sales still rising as commercial craft slows . |

| Sanitation Impact | CIP systems reduce infection rate. This speeds production by 15% . |

| Sensory Quality | Good trub separation improves final flavor by 10–15% . |

Fermenter Market Trends & Brewing Impact (2024–2033)

$1.5–3.2B Market Size (2024)

6.2%–7.5% Annual Growth (CAGR)

22% ↓ Contamination Drop with CIP

Global Beer Fermenter Market: 2024 vs. 2033

Key Growth Drivers:

Homebrew adoption Microbrewery expansion CIP technology Automation

Fermenter Accessories and Upgrades

- Fermenter Lid & Seal: Keep a tight fermenter seal to prevent oxygen.

- Ball Lock Posts or Tri-Clamp Fittings: Useful for pressure fermentation or sampling port additions.

- Thermowell & Fermentation Thermometer: Tracks fermentation temperature inside.

- Racking Arm & Sampling Port: Helps to move beer off trub.

- Spunding Valve: Maintains set pressure.

All these fermenter accessories, from a bung to a gasket, make brewing smoother. Doing so leads to beer clarity.

Why Brewers Worldwide Trust Micet for Their Fermentation Equipment

You want reliable brewing equipment. You crave a fermenter that ensures consistent souring fermentation or bright, hoppy ales.

Micet can help. Our line covers brewing equipment, fermentation tanks, distillation equipment, and more. We handle craft brewery equipment for big and small setups. We even design brewery layouts.

With 15 years of experience, Micet invests in R&D, production, and sales. We have 12 service centers worldwide. Our 3-year warranty on tanks and 1-year warranty on auxiliaries show our quality. Our aim is top-tier beer. Our team, led by CEO Nancy, leverages international sales expertise. The production director and quality inspectors focus on every detail. The service team’s 22 years of combined skill guides each project.

Ready to set up your microbrewery or explore advanced conical fermenters? Check out our site. Get customized solutions from Micet. Our references span 1000 breweries in 86 countries. Let us help with CIP (Clean-in-Place) systems, stainless steel fermenters, or bright tanks.

Explore Related Brewing Equipment and Fermentation Solutions

Explore our nano brewery equipment to experiment with small-scale fermentations.

Check out our craft beer brewing equipment for top-level conical fermenters.

Browse our latest beer fermenters to see how we integrate spunding valve technology.

Find more about our micro brewery equipment solutions for professional expansions.

Want to see advanced stainless steel conical fermenter designs? Check this out.

Conclusion

Beer fermenters are central to the brewing process. They guide wort through primary fermentation, secondary fermentation, or even souring fermentation. Conical fermenters, bucket fermenters, or carboy fermenters all play roles. Temperature control, CIP cleaning, and the right yeast strain matter.

Stainless steel fermenters with CIP (Clean-in-Place) systems keep things sanitary. Plastic fermenters are cheaper. Glass fermenters offer visibility. A spunding valve helps with pressure fermentation. Dry hopping, cold crashing, and final packaging all occur around these vessels.

Whether you are a new brewer or advanced, keep an eye on sanitization, headspace, fermenter volume, and bottle fermentation procedures. That ensures consistent, tasty beer. The synergy of advanced manufacturing from brands like SS Brewtech, Speidel, Spike Brewing, or from integrated solutions by Micet, powers the world of beer.

Brewers big and small—be they Sierra Nevada Brewing Co., Laguna’s, or local enthusiasts—understand that a solid fermenter is the heartbeat of craft beer production. The right fermentation chamber or bright tank setup can revolutionize your next brew. Follow fermentation best practices, manage oxygen exposure, do a diacetyl rest if needed, and sample for clarity.

Micet stands by to guide you. From nano fermenters to large-scale microbrewery equipment, we deliver solutions. Let’s craft something amazing together.