We frequently receive inquiries regarding the type of air compressor that customers should purchase. While we strongly advise consulting a local, reputable air compressor dealer to discuss your specific requirements, we do know a thing or two about various compressor types and their advantages. In this blog, I will focus on a specific category of air compressor: Sliding Vane Compressors.

Sliding Vane Compressors (also referred to as Rotary Vane Compressors) fall under the category of positive displacement compressors (as opposed to dynamic). More specifically, they are a form of rotary compressor in the positive displacement family. You can see this from the following diagram:

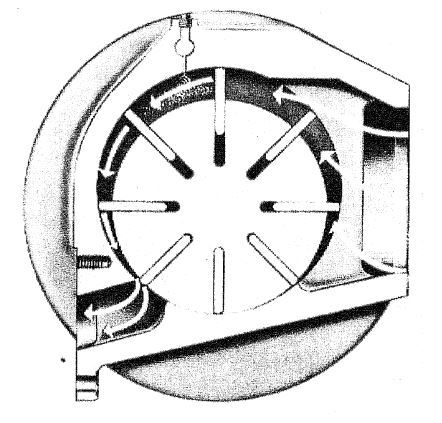

In positive displacement compressors, a specific volume of air is confined within a compression chamber. This volume is then mechanically compressed, resulting in an increase in pressure. Sliding Vane Compressors are composed of an external housing, known as the stator, and an internal circular rotor that is positioned eccentrically. The rotor features radially arranged (and sometimes offset) slots that accommodate vanes. As the rotor spins, centrifugal forces act on the vanes, causing them to extend outward and press against the inner surface of the stator bore. This interaction generates compression zones formed by the vanes, the rotor surface, and the stator bore.

Due to the eccentric positioning of the rotor, the volume of these compression zones decreases as the gap between the rotor surface and the stator narrows. As the rotor rotates counterclockwise, the vanes are pushed back into the rotor slots while maintaining contact with the stator surface. This reduction in the compression zone results in an increase in air pressure.

The advantages of the Sliding Vane Compressor are as follows:

- Compact size

- Relatively low initial cost

- Vibration-free operation – no special foundation needed

- Routine maintenance includes basic lubricant and filter changes.

A few of the disadvantages are:

- Lubricant gets into the compressed air stream, requires an air/lubricant separation system.

- Requires periodic lubricant change and disposal

- Less efficient than rotary screw type

- Not as flexible as rotary screw in terms of capacity control in meeting changing demands

If you would like to discuss your compressed air application, then give us a call!

Al Wooffitt

Application Engineer

Send me an Email

Find us on the Web

Like us on Facebook

Twitter: @EXAIR_AW

Al Wooffitt

Application Engineer

Send me an Email

Find us on the Web

Like us on Facebook

Twitter: @EXAIR_AW

- Compressed Air & Gas Handbook. Diagram of Compressor Technologies.